Description

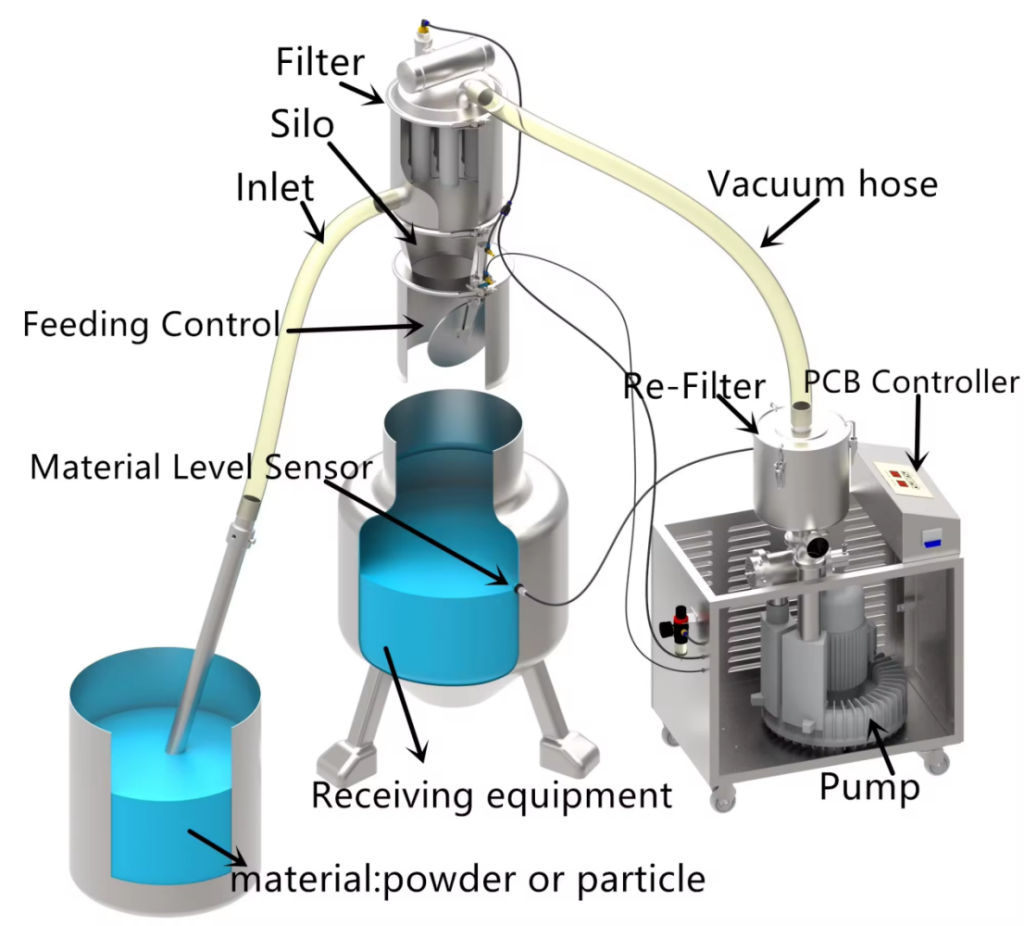

Le convoyeur à vide utilise une pompe à air vortex/un ventilateur Roots pour pomper l'air, mettre l'entrée de la buse d'aspiration et l'ensemble du système dans un certain état de vide, puis les matériaux en poudre et granulaires seront aspirés dans la buse avec l'air extérieur pour former un flux de matériau, et passer à travers le tuyau d'aspiration jusqu'à la trémie, enfin séparer le gaz et le matériau dans la trémie. Les matériaux séparés entrent dans l'équipement de réception. L'alimentation-décharge est complétée par l'ouverture et la fermeture continues de la vanne pneumatique à trois voies/du cylindre à spirale, et l'ouverture et la fermeture de la vanne pneumatique à trois voies/du cylindre à spirale sont contrôlées par le boîtier de commande de puissance.Centre de produits

Contactez-nous

- Tél.: +8613912907037

- E-mail: selenaz@jsozeo.com

- WhatsApp: +8613912907037

- Adresse:No.6 Longzhong Road, district de Luhe, Nanjing, Jiangsu, Chine, 211500

Présentation du produit

Fonctionnalité

- Le convoyeur à vide est équipé d'un dispositif de soufflage d'air comprimé. Chaque fois que le matériau est déchargé, l'impulsion d'air comprimé souffle le filtre pour faire tomber la poudre adsorbée à la surface du filtre, assurant le fonctionnement normal du matériau aspiré

- Le filtre est facile à démonter et à nettoyer

- Résoudre le problème de fuite de poudre, respectueux de l'environnement

- Pièces en contact avec la poudre en acier inoxydable 304

Construction

Paramètre

| Convoyeur à vide | ||||

| Modèle | Livraison (kg/h) | Volume de l'entrepôt (L) | Pression de service (Mpa) | Puissance du moteur (kW) |

| ZKS-3 | 500-800 | 12 | 0.4-0.6 | 5.5 |

| ZKS-4 | 800-1200 | 42 | 0.4-0.6 | 7.5 |

| ZKS-7 | 1500-2500 | 60 | 0.4-0.6 | 11.5 |

| ZKS-10-6 | Environ 6000 (lors d'une distance de transport de 10 m) | 120 | 0.4-0.6 | 7.5 (Fan de racines) |

| ZKS-20-5 | Environ 5000 (lors d'une distance de transport de 10 m) | 280 | 0.4-0.6 | 11 (Fan de racines) |